Top 30 Technical Interview Questions Asked at Blue Origin (2025 Edition)

Get ready for your Blue Origin technical interview with these 30 real-world questions across software, aerospace, mechanical, and electrical roles.

Preparing for a Blue Origin technical interview means being ready for challenging questions in software, aerospace, mechanical, electrical, propulsion, and systems engineering. Below, we break down 30 real-world technical interview questions (2025 edition) by category, with example answers and tips. Use these as a guide to what Blue Origin technical interview questions to expect, and how to approach them like a pro.

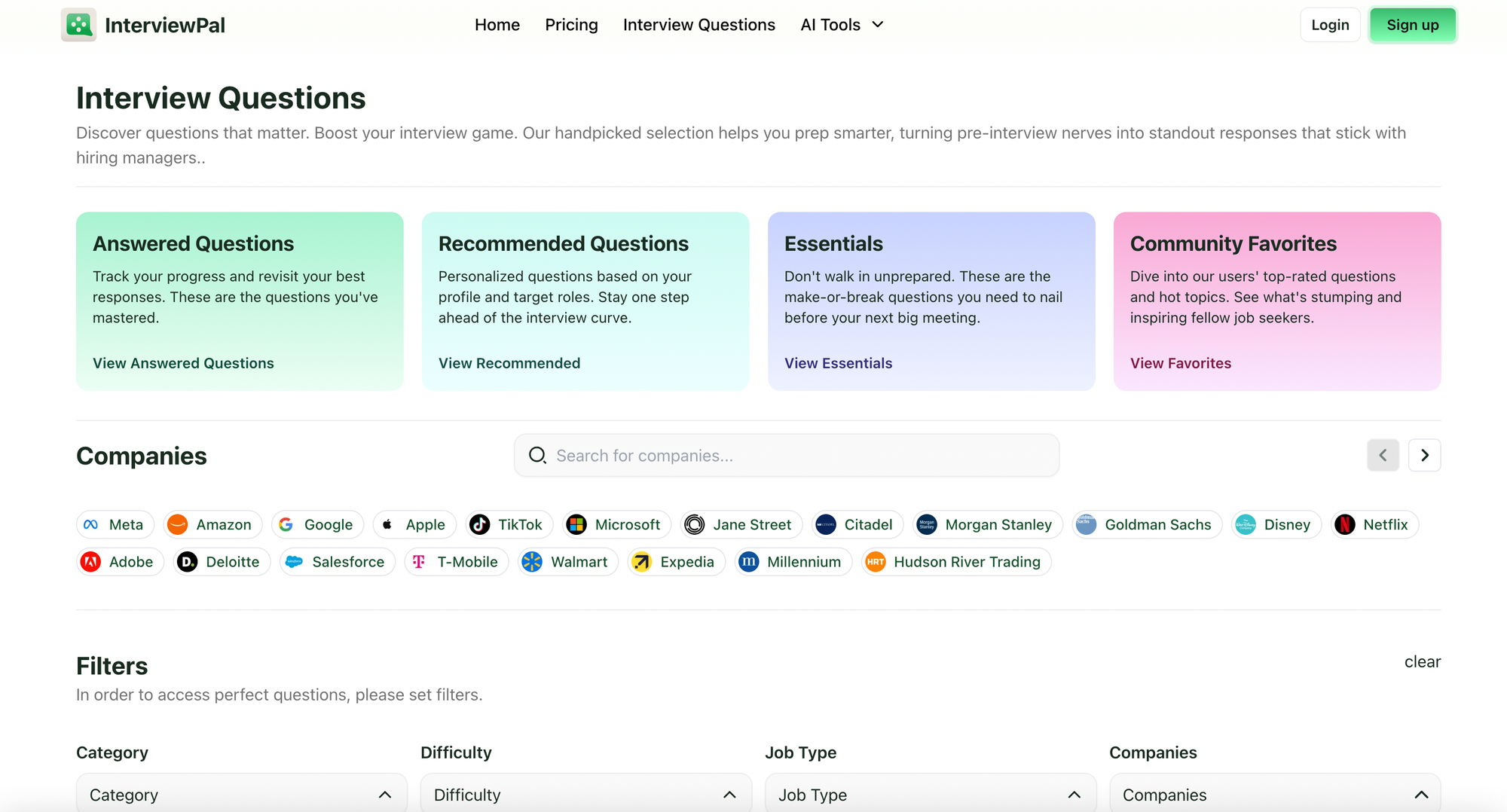

Our complete Blue Origin Interview Questions Database

Software Engineering Interview Questions at Blue Origin

Software engineering interviews at Blue Origin typically involve coding challenges and questions about building reliable software for space systems. In fact, algorithm and coding problems come up in the vast majority of Blue Origin software interviews.

You should be ready to write code, discuss optimization, and demonstrate knowledge of embedded systems and best practices.

- Coding Challenge: Given an array of integers, find all the duplicate values and return them. (Interviewers often pose problems like this to test your coding skills and understanding of data structures.)

Sample Answer Approach: First, clarify the expected output and any constraints (e.g. memory or time limits). A straightforward solution is to use a hash set to track seen numbers and collect those seen again. This runs in O(n) time. For example, iterate through the list, check each number against a set, and if it's already present, add it to a result list. Discuss trade-offs: using a set uses extra space, while sorting the list to find duplicates would be O(n log n) but save space. - Real-Time Systems: What key considerations go into developing software for a real-time embedded system, such as a rocket’s flight control software?

Answer Outline: Emphasize timing, determinism, and safety. Explain that in a real-time aerospace system, tasks must meet strict deadlines; you would use a real-time operating system (RTOS) or optimized interrupt-driven design. Discuss avoiding dynamic memory allocation during flight (to prevent unpredictable delays), watchdog timers to reset unresponsive software, and thorough testing for race conditions or deadlocks. Highlight the need for fail-safes because software malfunctions could endanger the mission. - Software Integration: How do you approach integrating a new software module into an existing aerospace system without disrupting functionality?

Sample Answer: Integration should be done methodically. Begin with a feasibility analysis to understand interfaces and impacts on the existing system. Next, use a phased strategy: unit test the new module in isolation, then perform integration testing in a staging environment to see how it interacts with the current software. One might deploy the update incrementally (feature flags or a simulation mode) and monitor outputs closely. Throughout, maintain clear communication with the team and have rollback plans. For example, if adding a new guidance algorithm to flight software, you’d test it off-line with recorded flight data, verify performance, then gradually enable it in real flights alongside the legacy system until fully validated. - Code Quality & Safety: What strategies do you use to test and validate software for mission-critical applications? (Blue Origin cares about quality and safety in code.)

Answer Framework: Explain a multi-layer testing approach: unit tests for individual functions, integration tests for modules, hardware-in-the-loop simulations for the full system, and code reviews following strict guidelines (like MISRA for C/C++ in safety-critical code). Mention using static analysis tools to catch bugs, and performing stress tests (e.g. high CPU load or sensor data spikes) to ensure the software behaves predictably under extreme conditions. - Concurrency and Reliability: Can you give an example of a potential race condition in multi-threaded code and how to prevent it?

Answer Tips: Define a race condition (two threads accessing/modifying shared data concurrently leading to unpredictable results). A simple example is two threads incrementing a global counter without locks – the final count could be wrong. To prevent it, explain using mutex locks or semaphores around critical sections, or employing atomic operations. In an aerospace context, you might describe protecting a shared sensor reading or command queue so that data remains consistent. Emphasize that careful synchronization and thorough testing (including stress tests and code review) are essential to avoid concurrency bugs in flight software.

Aerospace Engineering Interview Questions at Blue Origin

Aerospace engineering interviews at Blue Origin will probe your knowledge of aerodynamics, orbital mechanics, and flight dynamics. Be prepared for questions about rocket flight principles, spacecraft trajectories, and the unique challenges of operating in the space environment.

- Suborbital vs. Orbital Flight: What are the key differences between suborbital and orbital spaceflight?

Sample Answer: Explain that suborbital flights (like Blue Origin’s New Shepard) go above the Kármán line (the edge of space) and then come back down without achieving orbit. They have lower velocity requirements (on the order of 1–3 km/s) and typically result in a short microgravity experience before reentry. Orbital flights, on the other hand, must reach a much higher horizontal velocity (~7.9 km/s for low Earth orbit) so that the vehicle continually falls around Earth rather than back to the ground. Orbital missions face greater challenges: they require significantly more energy (fuel) and produce higher heating on reentry since the spacecraft is moving faster when it hits the atmosphere. Additionally, orbital vehicles need precise trajectory insertion and often require multiple stages or engines to achieve the necessary speed, whereas suborbital flights are usually single-stage. This distinction affects vehicle design, as orbital rockets like New Glenn are larger and more complex than suborbital rockets. - Aerodynamic Stress (Max Q): During launch, what is Max Q and why is it important?

Answer: Max Q is the point during a rocket’s ascent where aerodynamic pressure on the vehicle is at its maximum. It occurs at a balance between increasing speed and decreasing air density with altitude. Engineers design rockets to throttle down thrust when approaching Max Q to reduce forces on the structure and avoid stress or damage. You would explain that understanding Max Q is crucial for aerospace engineers because it dictates structural requirements; the vehicle must withstand these peak forces. Blue Origin’s rockets, like all others, are engineered to survive Max Q loads with some safety margin, and flight controllers may adjust engine power during this phase to manage stresses. - Guidance and Control: How is a rocket steered during flight? Describe mechanisms like engine gimbaling or control surfaces.

Answer Outline: Rockets lack the aerodynamic steering of airplanes (except possibly small fins in atmosphere), so primarily they use engine gimbaling – pivoting the rocket engine nozzle to vector thrust in the desired direction. Explain that by tiny adjustments to the angle of thrust, the rocket can pitch, yaw, or roll. Many launch vehicles, including Blue Origin’s, have actuators that tilt the engines based on guidance commands. In space (vacuum), gimbaling still works, and additionally reaction control systems (RCS) – small thrusters – can be used for fine attitude adjustments when engines are off or for roll control. If the question expects multiple methods, mention aerodynamic fins or vanes (used during the early ascent or landing in some designs) and how they become ineffective in thin air. The key is demonstrating understanding of closed-loop guidance: sensors (like gyroscopes and accelerometers) feed vehicle orientation data to a flight computer, which then commands actuators (gimbal or thrusters) to keep the rocket on course. - Orbital Mechanics: What is a Hohmann transfer orbit and when would you use one?

Answer: A Hohmann transfer is an efficient two-burn orbital maneuver to move a spacecraft from one circular orbit to another. It consists of an elliptical transfer orbit that tangentially touches both the initial and target orbits. Explain that you use a Hohmann transfer when you want to raise or lower an orbit (for example, going from a low Earth orbit to a higher orbit or to a geostationary orbit) with minimal fuel. The spacecraft performs one engine burn to exit the initial orbit into the elliptical transfer, then a second burn at the other end of the ellipse to circularize into the new orbit. This method is fuel-efficient but takes longer time compared to more direct (but higher energy) transfers. - Re-entry Challenges: What are the main challenges a spacecraft faces during re-entry into Earth’s atmosphere?

Answer Highlights: Re-entry is extremely demanding due to intense aerodynamic heating (causing temperatures of thousands of degrees on the heat shield), high structural loads from deceleration (several G’s of force), and plasma formation that can cause communications blackout. A good answer would mention the need for thermal protection systems (like ablative heat shields or insulating tiles) to prevent the spacecraft from burning up. Also discuss controlling the re-entry trajectory to manage g-forces and ensure accuracy of landing – too steep and you burn up or overload the structure, too shallow and you skip off the atmosphere. Spacecraft design must account for these factors with robust materials and often a blunt body shape (to create a shockwave that keeps most hot plasma away from the vehicle). Blue Origin’s suborbital capsule, for instance, experiences some of these challenges on a smaller scale, but an orbital vehicle returning from space (when Blue Origin advances to that) faces much higher energy and thus greater challenges.

Mechanical Engineering Interview Questions at Blue Origin

Mechanical engineering candidates at Blue Origin are tested on their understanding of design principles, materials, and manufacturing processes. Be prepared for questions about structural analysis, thermal stresses, and how you would build and test hardware for the extreme conditions of space. You might even be asked to sketch or interpret fundamental concepts – for example, one reported interview question was to draw a stress–strain diagram and explain its features

- Extreme Environments: Describe your approach to designing a mechanical system that must operate under extreme temperature variations (from the heat of launch to the cold of space).

Sample Answer: Start with material selection. Choose materials that maintain integrity across the temperature range – for instance, titanium alloys or Invar (which has very low thermal expansion) for components that must hold tight tolerances. I would consider thermal expansion coefficients to ensure parts don’t crack or seize when temperatures swing. Next, discuss analysis and testing: use thermal simulations (finite element analysis for thermal stress) to predict how components behave in vacuum cold or during atmospheric reentry heating. If designing, say, a rocket engine valve, I might design expansion gaps or use flexible joints to accommodate expansion. Also mention thermal protection or control: maybe insulating layers or active heating/cooling if needed to keep components within safe operating temps. Finally, I would validate the design through testing – for example, put the system in a thermal chamber cycling between extremes, and perform functional tests. By combining careful material choice, simulation, and testing, you ensure the mechanism will work reliably whether it’s -150°C in space or +1000°C during a high-speed reentry. - Fundamentals (Stress–Strain): Can you explain the key features of a stress–strain curve for a typical metal?

Answer: A stress–strain diagram plots material stress (force per area) against strain (deformation). Key regions to mention: the elastic region (a linear portion where the material returns to original shape when load is removed, governed by Young’s Modulus slope), the yield point (where permanent deformation begins – beyond this, the material yields and won’t fully recover), the plastic region (material deforms permanently; the curve may flatten or harden depending on the metal), and the ultimate tensile strength (UTS) at the peak of the curve (maximum stress the material can withstand). After UTS, the curve often drops due to necking, leading to fracture. An interviewer wants to see that you understand yield strength (design limit for no permanent deformation) and the safety margin to avoid reaching it. Also mention toughness (area under the curve) and difference in behavior for ductile vs. brittle materials (ductile metals have a pronounced plastic region and noticeable yield point, brittle materials fail near the elastic limit). - Advanced Manufacturing: Have you used additive manufacturing (3D printing) for aerospace components, and what are its pros and cons?

Answer: Yes, I have experience with metal additive manufacturing (e.g. Direct Metal Laser Sintering) for aerospace parts. Pros: It allows complex geometries that are impossible or very costly to make via machining (like internal cooling channels in a rocket engine injector). It can also reduce part count by printing an assembly as one piece and shorten development time by enabling rapid prototyping. Cons: The printed material’s properties can differ (e.g. anisotropy or internal porosity), so you need careful process control and often post-print heat treatment or machining for critical surfaces. Additionally, size is limited by printer volume and the process can be expensive for large production runs compared to traditional methods. I would add that Blue Origin and others have successfully used 3D printing for engine parts, so knowing when to apply it – typically for complex, weight-optimized components needed in low volumes – is key. - Process Optimization: Tell me about a time you optimized a manufacturing process for a mechanical component. (Interviewers want to see your problem-solving in production or prototyping scenarios.)

Answer Framework: Outline the situation, for example: you noticed a bottleneck or waste in the production line for a rocket part. Explain the steps you took – perhaps you applied Lean manufacturing principles or a Six Sigma approach to identify inefficiencies. Maybe you reconfigured the workflow or introduced a jig/fixture to speed up assembly. Mention quantifiable results: e.g. “By rearranging the machining steps and introducing in-process quality checks, I reduced production time by 20% and defect rate by 5%.” The key is to show that you can improve throughput without sacrificing quality, which is crucial in aerospace manufacturing. (Blue Origin values efficiency but never at the cost of precision or safety.) - Design Tools: What design and analysis tools are you proficient in, and how have you used them in complex mechanical projects?

Answer: List relevant tools like CAD software (e.g. SolidWorks, CATIA, or NX) for 3D modeling and FEA software (ANSYS, Abaqus) for structural/thermal analysis. Provide a concrete example: “In my last project, I used SolidWorks to design a satellite component and then ran finite element analysis in ANSYS to verify it could withstand launch vibration. The simulation highlighted a stress concentration, so I iterated the model (adding a fillet to reduce the stress) and re-ran FEA to validate the fix.” Emphasize that you understand how to go from modeling to analysis to real-world testing. The interviewer wants to gauge your hands-on experience with these engineering tools because Blue Origin’s mechanical engineers heavily use them to design and validate parts before cutting metal.

Electrical Engineering Interview Questions at Blue Origin

Electrical and avionics engineering interviews at Blue Origin cover circuits, sensors, and robust electronics design for spacecraft. You may encounter fundamental questions about electronics as well as scenario-based problems. For instance, candidates have been asked to explain how common sensors work and even to troubleshoot mismatched sensor readings in a test setup.

- Sensor Fundamentals: How does a thermocouple work, and what is the difference between a thermocouple and an RTD for measuring temperature?

Sample Answer: A thermocouple consists of two dissimilar metal wires joined at one end. It works on the Seebeck effect – when the junction is heated, it produces a voltage proportional to temperature. By measuring that voltage and referencing cold-junction compensation, you can determine the temperature at the hot junction. An RTD (Resistance Temperature Detector), in contrast, is usually a fine wire (often platinum) whose electrical resistance increases with temperature in a known way. You measure its resistance to get temperature. Thermocouples can handle very high temperatures and are self-powered (just need a voltmeter), but their output is nonlinear and low voltage (requiring amplification and reference). RTDs provide very accurate and stable readings in a more limited temperature range and have a near-linear response, but they need an excitation current and can be slower to respond and less robust at extreme highs. In summary: use a thermocouple for extremely high temps (like engine exhaust) or fast response, and an RTD when you need precision and stability at moderate temperature ranges. - Troubleshooting Scenario: Imagine you have two pressure transducers on the same propellant line: one reads 1000 psi and the other 100 psi at the same time. What steps would you take to troubleshoot the discrepancy?

Answer: This scenario tests systematic troubleshooting. I would verify the instruments first – check if one sensor is mis-calibrated or damaged. For example, ensure both were zeroed properly and perhaps swap their positions or connect a known reference gauge to see if the readings follow the sensor or the port. Next, inspect the system setup: are the sensors actually measuring the same point? Perhaps one is behind a regulator or a partially closed valve. Ensure there’s no blockage (like a clogged line or filter) isolating one sensor. I’d also consider the data acquisition: is there a software or unit conversion error? After each step, I’d methodically rule out causes. In practice, one might find that one transducer had a faulty diaphragm causing a bad reading, or it was placed in a spot that doesn’t see full pressure. The key is a logical approach: swap components, verify calibration, check the physical installation, and use external references until the cause is identified. - EMI/EMC Design: What is electromagnetic interference (EMI) and how do you mitigate it in an aerospace electronic system?

Answer: EMI is unwanted noise or interference in electrical systems caused by electromagnetic radiation from other devices (for example, a high-power radio transmitter or a switching circuit can induce noise in nearby cables). In spacecraft or rocket systems, EMI can disrupt sensors or communication. Mitigation strategies include shielding (enclose sensitive electronics or cables in grounded metal shields to block external fields), filtering (use filters like capacitors, ferrite beads, or common-mode chokes on lines to suppress high-frequency noise), and proper grounding schemes (avoiding ground loops and ensuring a single-point ground). Also, design techniques like twisting wire pairs and separating signal lines from power lines help reduce coupling. I would mention following EMI/EMC standards (like MIL-STD-461) and performing testing. For example, in designing an avionics box, I might add shielding on the enclosure and filter the power input to ensure it doesn’t both emit or suffer from EMI. Blue Origin’s electronics must operate amidst powerful radar and radio systems and the noisy electromagnetic environment of a rocket, so controlling EMI is critical for reliable operation. - Digital Systems: Explain what an FPGA is and why one might be used in a spacecraft’s avionics.

Answer: An FPGA (Field-Programmable Gate Array) is an integrated circuit that can be programmed (configured) after manufacturing to implement custom digital logic circuits. Essentially, it’s a hardware fabric of logic gates that you can wire up via code (HDL). In aerospace avionics, FPGAs are often used because they combine the performance of hardware with the flexibility of software. For example, they can perform parallel processing tasks at high speed, which is useful for real-time data processing (like sensor fusion or image processing) where a general-purpose CPU might be too slow. FPGAs can also be reprogrammed for updates or different missions without changing hardware. A good example is using an FPGA for a spacecraft’s guidance computer: it could handle multiple sensor inputs and control outputs deterministically. I would note that FPGAs are also chosen for reliability – you can design logic that is simpler and more robust to radiation effects than a complex CPU. However, one must implement mitigation for radiation (like TMR – triple modular redundancy – inside the FPGA) to ensure it doesn’t glitch from cosmic rays. Overall, highlight that FPGAs provide a speed and reconfigurability advantage in mission-critical electronics. - Rugged Electronics: What environmental factors must be considered when designing electronic systems for spaceflight, and how do you address them?

Answer: Spaceflight electronics face harsh conditions. Key factors: vibration and shock (during launch), vacuum (no air for cooling, outgassing of materials), temperature extremes (electronics may see very cold or hot conditions in space or during engine firing), and radiation (both ionizing radiation and single-event effects from cosmic rays). I would explain design approaches for each: to handle vibration, use robust PCB mounting, potting or conformal coating components, and choose high-reliability connectors so nothing loosens (Blue Origin does extensive vibe testing for this). For thermal, use thermal conduction paths since convection isn’t available in vacuum – for instance, mounting power components to a chassis that serves as a heat sink, and possibly thermostatically controlling heater elements for components that need to stay warm. For vacuum, ensure materials are space-rated (no volatile compounds that could outgas and contaminate optics or sensors) and that components can operate in low pressure (some capacitors or batteries need pressure to function properly, so you might need them in a pressurized container). Lastly, for radiation, use radiation-hardened parts where possible, incorporate error-correcting memory, watchdog timers, and redundancy. By addressing vibration, thermal, vacuum, and radiation factors in the design phase, we make avionics that can survive the journey from launch pad to space and back.

Propulsion Engineering Interview Questions at Blue Origin

Propulsion engineering interviews focus on rocket engines and fluid systems. Blue Origin designs and builds its own engines (like the BE-3 and BE-4), so expect in-depth questions on how rocket engines work, performance metrics, and troubleshooting engine issues. You should be comfortable discussing combustion, thermodynamics, and propellant technologies.

- Rocket Performance: What is specific impulse and why is it important in rocket engine performance?

Sample Answer: Specific impulse (Isp) is a key measure of rocket engine efficiency. It represents the impulse (thrust * time) produced per unit of propellant weight consumed per second, essentially how effectively a rocket uses its fuel. In practical terms, it’s often given in seconds – higher Isp means the engine gets more thrust from each kilogram of propellant. I would explain that Isp is analogous to fuel economy for rockets: an engine with 350 seconds Isp is more efficient than one with 250 seconds. It’s important because when designing a vehicle, higher specific impulse means you need less propellant to achieve the same delta-V (change in velocity), which can drastically reduce the vehicle’s mass or increase its payload. For example, Blue Origin’s BE-3 (liquid hydrogen/liquid oxygen engine) has a high Isp (in vacuum ~450 seconds) due to hydrogen’s efficiency, which is great for upper stages. In summary, specific impulse tells us how long a pound of fuel can produce a pound of thrust – a fundamental metric to compare engine efficiencies. - Turbopump Mechanics: Explain how a turbopump in a liquid rocket engine works.

Answer: A turbopump is essentially a very high-speed pump driven by a turbine, and it’s used to feed propellants into the combustion chamber at high pressure. I’d break it down: liquid propellants (fuel and oxidizer) are stored at relatively low pressure in tanks; the turbopump’s job is to rapidly pump these into the engine. It has a pump section (often one for fuel, one for oxidizer) – typically a centrifugal pump – and a turbine section. The turbine is driven by hot gas, which is usually generated by a small burner called the gas generator or via exhaust from a preburner (depending on engine cycle). As the hot gas expands through the turbine, it spins the turbine wheel, which is on a shaft connected to the pump impellers. This spinning pumps the fuel and oxidizer to the high pressures needed for combustion. In a staged combustion engine (like Blue Origin’s BE-4), the turbopump is fed by preburner gases and the exhaust goes into the main chamber; in a gas-generator cycle, the turbopump exhaust is dumped separately. Key points: turbopumps allow for lightweight tanks (since tanks don’t need to be as high pressure as the chamber), but they are extremely complex rotating machinery (tens of thousands of RPM, requiring precision bearings and careful design to avoid cavitation and thermal stress). Interviewers asking this want to see you understand both the function and the challenges (e.g., thermal management, seals, avoiding pump cavitation, etc.). - Propulsion Trade-offs: Compare liquid propellant rocket engines to solid propellant rockets. What are the advantages and disadvantages of each?

Answer: Liquid-fueled engines (like Blue Origin’s) use liquid fuel and oxidizer that are pumped into a combustion chamber. They are throttleable (you can regulate thrust by controlling propellant flow) and even shut down/restartable, providing flexibility during flight. They generally have higher specific impulse (especially cryogenic propellants like LOX/LH2) and can achieve high performance. The downside is complexity: they require pumps, valves, plumbing – lots of parts that can fail or require careful engineering. Solid rockets have propellant mixed into a solid grain that burns once ignited. They are simpler (no moving parts like pumps) and very stable to store (long shelf life, ready to fire on short notice, which is why they’re used in missiles). They can provide high thrust and are often used as boosters. However, solids cannot be easily throttled or stopped once ignited – they burn to completion – and they usually have lower Isp than liquids. Also, controlling their thrust profile requires shaping the propellant grain, which is less flexible than adjusting valves in a liquid engine. I would conclude that liquid engines are preferred for missions needing precise control (like orbital insertion or human spaceflight where you may need to abort), whereas solid rockets are useful for sheer power and simplicity (like initial boost stages or military uses). - Engine Cycles: Blue Origin’s BE-4 engine uses a staged combustion cycle. How does a staged combustion cycle differ from a gas-generator cycle in rocket engines?

Answer: In a gas-generator cycle, a small fraction of propellant is burned in a separate gas generator to drive the turbopumps, and that hot gas (after powering the turbine) is exhausted overboard (dumped, not going through the main chamber). This is simpler but wastes some propellant energy. In a staged combustion cycle, nearly all propellant goes through a preburner (or preburners) and the resulting hot gas from driving the turbine is fed fully into the main combustion chamber. Essentially, nothing is wasted: the engine uses an oxidizer-rich or fuel-rich preburner to pump the propellants, then burns the remaining reactants in the main chamber. This is more efficient (higher performance) because all propellant contributes to thrust, but it’s much more complex – the turbopump and preburner have to handle hot, high-pressure mixtures (often corrosive if oxidizer-rich). For example, BE-4 is oxidizer-rich staged combustion using methane and LOX, which gives it high efficiency but required solving materials challenges for running oxygen-rich hot gas through turbines. Meanwhile, something like the older gas-generator engines (e.g. Apollo’s Saturn V first stage engines) were easier to develop but slightly less efficient. I’d note staged combustion typically yields higher chamber pressures and better ISP, which is why modern engines (RD-180, BE-4) use it, despite the engineering difficulty. - Troubleshooting Propulsion: If a test of a new rocket engine showed oscillations or instability in the combustion chamber (aka “engine chugging” or vibrations), how would you go about diagnosing and fixing the issue?

Sample Answer: Combustion instability is a known challenge in rocket engines. My approach would start with data: examine pressure sensor readings in the chamber to characterize the oscillation frequency (is it a low-frequency “chug” or a high-frequency screech?). If it’s low-frequency, it could be coupling with feed system oscillations – I’d check the propellant lines and tanks (perhaps needing damping or adjusting regulator valves). If it’s high-frequency (acoustic mode in chamber), I’d look at the injector design – often instabilities arise from how propellants are mixing and burning. One might test different injector face designs or add baffles or helmholtz resonators (acoustic cavities) to disrupt pressure waves. I’d also scrutinize the turbopump for oscillations that might feed into the chamber (feedback loops). In diagnosing, we might run instrumented tests, vary one parameter at a time (for example, try different injector geometries, or add a damper in the fuel line) to see the effect. Fixing it could involve design changes like adding acoustic dampers in the chamber or modifying the injector pattern to break up coherent oscillation modes. I would mention that solving combustion instability is often iterative: test, analyze, simulate (CFD/combustion simulation), adjust, and test again. The key is to methodically isolate the cause – whether it’s a feed coupling or combustion dynamics – and then address it through design tweaks or added damping mechanisms. This answer shows the interviewer I understand both the phenomenon and the engineering process to resolve it.

Systems Engineering Interview Questions at Blue Origin

Systems engineering interviews at Blue Origin focus on the big picture: how different subsystems (software, mechanical, electrical, etc.) come together and how to ensure reliability and mission success. You’ll get questions on requirements, integration, and risk management. A strong candidate demonstrates they can think holistically and communicate across disciplines.

- Role of Systems Engineering: Why is systems engineering important in the development lifecycle of a spacecraft or launch vehicle?

Sample Answer: Systems engineering is like the glue that holds all the engineering disciplines together and ensures the final product meets its overall mission goals. I would explain that in a complex project (like a Blue Origin rocket), you have experts in propulsion, structures, avionics, software, etc., and each could optimize their piece in isolation – but the systems engineer makes sure all those pieces fit and function as a coherent whole. This includes defining clear requirements for each subsystem derived from top-level mission requirements, managing interfaces between systems (so that, for example, the thrust of an engine is within what the structure can handle, and the software knows the engine’s response characteristics). Systems engineering also tracks verification and validation – ensuring that every requirement is tested or analyzed, so nothing is left unproven before flight. It’s crucial for catching issues that might be overlooked when focusing on one part. For instance, a systems engineer might notice that a change in a battery subsystem could affect the thermal control system and flag that for the team. In summary, without systems engineering, you risk integration problems, cost overruns, and even mission failure; with it, you ensure all parts work in harmony, aligned to the same objectives. - Requirements Management: How do you handle changing requirements in the middle of an engineering project?

Answer: Changing requirements are common, especially as new information comes in or customer needs evolve. The key is a controlled process. I would first assess the impact: which subsystems are affected by the change? Engage all stakeholders (engineering leads, project managers) to do an impact analysis – in terms of performance, schedule, cost. Then follow a formal change control procedure: update the requirement in the requirements traceability system, and propagate those changes to subsystem specs. It’s important to maintain traceability, so every requirement change can be linked to design changes and test updates. I’d communicate clearly to all teams: for example, if the payload weight increased, the propulsion team might need a thrust boost and the structures team a stronger frame – everyone must know the new targets. Also, verify if any prior tests or analyses need redoing under the new requirements. Essentially, demonstrate that you maintain organization and rigor: no ad-hoc changes get implemented without review, and once approved, everything is re-baselined. Blue Origin likely uses systems engineering tools (like DOORS or similar) for requirements management, and I would ensure I’m familiar with that process. - Subsystem Integration: What steps would you take to ensure different subsystems (e.g. propulsion, avionics, structures) integrate smoothly in a rocket development project?

Answer: Integration starts early with good interface definition. I’d make sure there are clear Interface Control Documents (ICDs) between subsystems, specifying how they connect physically, electrically, and logically. For example, define the bolt patterns, data protocols, power levels, command sequences – everything that crosses subsystem boundaries. Next, plan for integration testing: don’t wait until all components are final. Use simulators or testbeds where possible (for instance, simulate the engine thrust feedback into the flight computer in a lab environment). I’d coordinate incremental integration: perhaps first integrate avionics and software in a hardware-in-the-loop setup, then introduce mechanical elements step by step. Throughout, communication is key – regular meetings where subsystem teams review interface issues or changes. If a change is needed (say the avionics box is heavier than expected), use the systems engineering process to evaluate impact on other subsystems (does structure need reinforcement? does center-of-gravity shift affect control?). I’d also emphasize configuration management – ensuring everyone is working with compatible versions of hardware and software. By being methodical and fostering cross-team visibility, we greatly increase the chances that when the full vehicle is assembled, it “just works” together, or at least that any issues are minor and quickly resolved. - Testing & Validation: Describe your approach to testing and validating that a full aerospace system meets all requirements.

Answer: I follow the V-model of systems engineering: as requirements are defined, we plan tests for each. First, verify components with unit tests (e.g., test an engine on a stand, test software modules independently). Then move to integration testing where components are combined – for example, a stage-level test where engines, tanks, and avionics are tested together to see if they perform as a unit. For validation, we check the system against the top-level requirements in environments that simulate real operation: thermal vacuum tests for space conditions, vibration tests to simulate launch, full mission simulations, etc. I would use both analysis and physical testing; some requirements (like “must survive X G’s”) can be analytically shown with margin, others (“achieve Y payload to orbit”) need a full flight test to truly validate. It’s important to have a traceability matrix – every requirement has one or more verification methods (test, analysis, inspection, demonstration) associated with it. Before flight, we’d conduct a Test Readiness Review and later a Verification Review to ensure all boxes are checked. If any requirement isn’t met in testing, have a plan (could be a waiver with justification or a redesign). Essentially, I ensure a rigorous campaign so that by the time we say “go for launch,” we have high confidence the system will perform as required because we’ve tested it in all imaginable ways on the ground. - Risk Management (FMEA): How would you carry out a Failure Modes and Effects Analysis (FMEA) for a critical system, say the rocket’s propulsion system?

Sample Answer: Performing an FMEA involves systematically brainstorming how each part of a system could fail and what the consequences would be. For a rocket propulsion system, I would break it down into components – pumps, valves, combustion chamber, controller, etc. – and for each, list possible failure modes (for instance, “fuel valve stuck closed”). Then for each failure mode, assess the effect on the overall system (e.g. if that valve stuck closed, the engine might shut down -> loss of thrust in flight). We assign a severity rating (engine-out could be mission-ending or even vehicle-loss if no mitigation, so very high severity). We also assign occurrence likelihood (based on past data or engineering judgment) and detectability (would we know it’s happening?). The product of those (or using a risk matrix) gives a risk priority. The goal then is to address high-risk items: propose mitigations or redundancies. In our example, perhaps have engine-out survival capability (multiple engines so one failing isn’t catastrophic) or a sensor to detect valve position and a backup valve if it fails. I’d document all this in an FMEA table. Finally, feed these mitigations back into the design – ensuring, say, critical sensors have redundancies, or inspection procedures are in place for high-risk components. By doing FMEA, we proactively think of what can go wrong and ensure that no single failure will unduly jeopardize the mission (a principle often called fail-safe or fault-tolerance). Blue Origin, like all launch providers, puts heavy emphasis on reliability, and discussing a structured approach like FMEA shows you would contribute to that reliability mindset.

ALSO READ: Getting a Job Offer at SpaceX: Interview Process and Top Questions To Practice

Preparing for Blue Origin’s technical interviews means brushing up on fundamentals and being ready to apply them to real-world scenarios. Expect each question to probe not just what you know, but how you think and solve problems. When answering, communicate clearly and confidently – imagine you’re explaining your reasoning to a teammate. Blue Origin values engineers who are technically sharp, detail-oriented, and passionate about space. By practicing questions like the ones above and formulating thoughtful answers, you’ll be well on your way to acing your Blue Origin interview and launching your career in the new space age!